Shrink Disc Coupling and Keyless Locking Assembiles, Locking Assemblies & Shrink Disc

The clamping process of this hydraulic disc takes less than 5 minutes! A comparable mechanical shrink disc is braced in several hours.

This significant time saving is of enormous importance, especially for test benches. Our design gives the customer also the opportunity to use sleeves for adapting different gearbox sizes including.90 degree gearbox .

This save much costs for the customer because it isn´t necessary to invest in different shrink disc coupling with different sizes.

Our engineering team supports our customers worldwide and advises from the design to the first use on site.

We want to be close to our customers and their projects and we live this way every day.

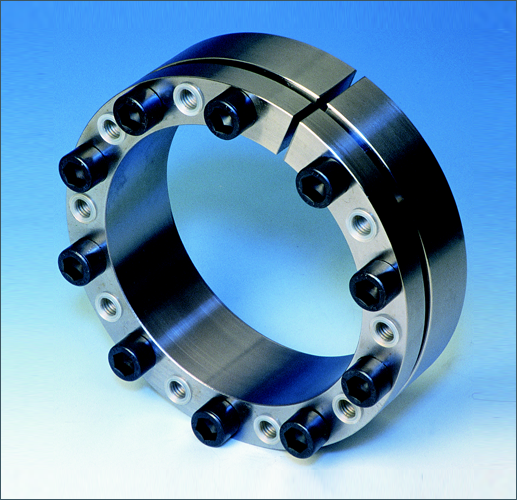

LOCKING ASSEMBLIES :

– Easy Assembly and disassembly

– Transmittable torque of 11Nm to 1,870,000 Nm

– Nominal diameter of 6mm to 700mm

– As a rust-free version available

– Special designs for higher bending moments available

Keyless Locking assembiles "Cone Clamping Elements" are internally clamping frictional connecting elements for backlash-free fastening of hubs on shafts. Depending on the design, Keyless locking assembiles consist of one or two conical pressure rings and one or more conical clamping sleeves. The conical pressure rings are pulled onto the conical surfaces of the clamping sleeve by tightening the clamping screws to the specified tightening torque and generate a radial force both inwards and outwards at the contact surfaces. This radial force produces a frictional connection between the cone clamping element and the shaft as well as the hub.

By means of this frictional shaft-hub connection, torques and axial forces can be reliably transmitted between the shaft and hub. Depending on the design, bending moments can also be transmitted with this type of connection. Compared to externally clamping connections such as "shrink discs", Keyless locking assembiles are located within the force flow. This means that the transmitted forces are passed from the shaft through the Keyless locking assembiles into the hub or vice versa. The Keyless locking assembiles itself must therefore withstand the forces, as it is the connecting element between the shaft and the hub.

Keyless Locking assembiles are available in a wide variety of designs, material and shapes. Depending on the requirements and specifications, we support our customers right from the product selection stage in order to find the perfect product for the application in question. Cone clamping elements are used, for example, to fasten chain wheels, flywheels, levers, belt pulleys, brake discs and conveyor belt drums.

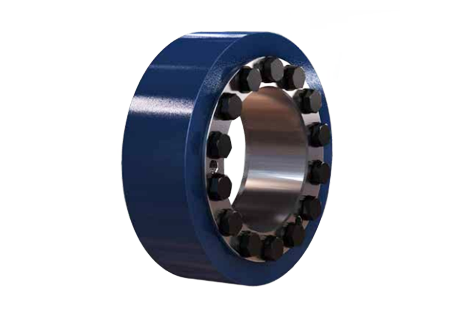

SHRINK DISCS (3 Parts) :

• SHRINK DISCS 3-PIECE

• Easy Assembly and disassembly

• Compensate for an elevated fit game

• Transmittable torque of 27Nm to 12.541.000 Nm

• Nominal diameter of 14mm up to 1000mm

• Various finishes and special finishes possible

Shrink discs are external clamping elements and consist of a pressure ring with a thread, a pressure ring with through holes, and a slotted inner ring. By Tightening the clamping screws with the specified tightening torque, the two pressure rings of the 3-array I shrink disc move on to the slotted inner ring to each other. By the use of tapered surfaces of the inner diameter of the inner ring, which exerts a radial clamping force on the hollow shaft is reduced. The clamping force is applied to the shrink disc connection is generated at the contact surfaces between the shaft and the hub of a Friction connection. Compared to the 2-part shrink discs & 3-part shrink discs have a larger cone angle.

This has the advantage that, in the case of disassembly is sufficient to loosen the clamping screws of the shrink disc connection to dismantle. On the base of the larger cone angle, which is located outside of the self-locking, can be dispensed with screws on the use of Extraction. This shortens the demo times of the day. Furthermore, it can be compensated for by the use of slotted inside a larger fit rings game between the hollow shaft and the shaft. Compared to the 2-part shrink discs, this is also the case of larger nominal diameters usual.

3-panel shrink discs are available in various designs. Depending on the space that is available, and the required torque, we will find together the right solution for you. Half or split versions as they come, for example, often to the wheels used with the 3-piece heat-shrink disc.

These properties of the 3-part shrink disc is a flexible product, which comes in a whole range of frictional shaft-hub-Connections, e.g. the drive technology, Oil and gas industry, wood industry or hollow shaft transmissions.

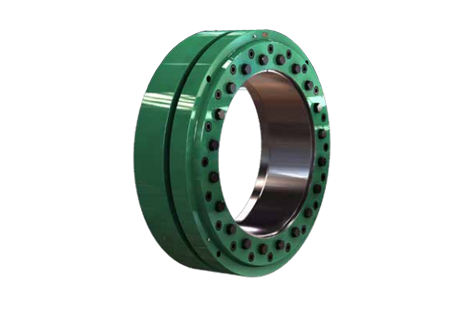

HYDRAULIC SHRINK DISCS :

• Application-Specific Interpretation/Application

• Quick clamping and releasing, in comparison to mechanical shrink discs

• The inner ring can be in different sizes to adapt

• Maintenance and repair by the customer is feasible

• Transmission of high torque

• Relatively low pressure

Wherever there is a requirement to connect the shaft and the hub safely and quickly with each other, the hydraulic clamping-adjustable shrink discs type "SHS" the company TAS Schäfer GmbH is used. With the TAS-SHS series of the TAS Schäfer GmbH has developed a hydraulically manages to tension shrink disc type "SHS", which applies everywhere in the drive technology for frictionally engaged shaft-hub-connections, use. By your quick and secure clamping, it is particularly suitable for the assembly on the test bench, and the clamping processes hole. Furthermore, the SHS series due to their unique characteristics, such as lower the required pressure to the margins, client-side implementation of the maintenance and repair, as well as the possibility to adapt the inner ring in different sizes.

Further development and the fulfilment of specific customer requirements, as well as the highest quality standards are today indispensable requirements of modern production.

The TAS-SHS product line has been used thousands of times in many areas of application for years. Hydraulically clampable shrink discs of the "SHS" type can be found worldwide, especially in wind turbines, on hydraulic motors and in gear test benches. The main function of a hydraulic tension shrink disc of the "SHS" type is to securely connect a shaft to a hub by means of frictional locking.

For example, between a drive shaft and a hollow transmission shaft. The hydraulically tension shrink disc creates a backlash-free connection by pressing the hub onto the shaft. This type of connection is mainly used to transmit torque. The hydraulic tension shrink disc of the "SHS" series only provides the required forces and does not transmit any forces or moments between the shaft and hub. It is therefore not in the power flow. With the SHS products from TAS Schäfer GmbH, the basic principle of mechanical, three-part shrink disc is retained. This principle has been tried and tested for a long time. The force-transmitting friction surfaces are strictly separated from the hydraulic system. Due to this strict separation, oil pollution of these surfaces can be prevented.

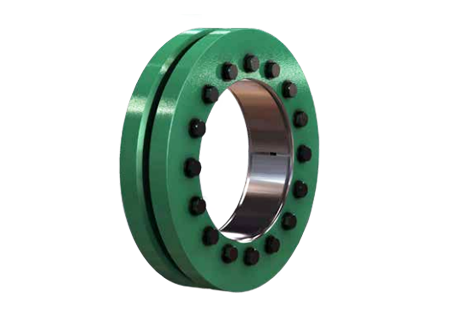

SHRINK DISCS, 2-PART (PATH-CONTROLLED) :

• Easy Handling

• Weight reduced

• Transmittable torque of 150Nm to 14.730.000 Nm

• Nominal diameter of 24mm to 950mm

• For low application temperatures

2-part shrink discs (displacement-controlled) are external clamping elements, which consist of a pressure ring and a sleeve. By Tightening the clamping screws with a predetermined tightening torque is pulled, the pressure ring axially on the sleeve. Through the use of conical surfaces of the inner diameter of the sleeve is reduced, resulting in a radial clamping force on the hollow shaft is to be exercised. The shrink disc connection, clamping force is applied to a Frictional connection is formed on the contact surfaces between the shaft and the hub. 2-Part shrink discs angle compared to the 3-part shrink discs a smaller Cone, it is located in the self-inhibition.

Due to the small cone angle, it is necessary that the sleeve has additional imprint thread. With the help of this fingerprint thread pressure ring and sleeve of the demo can be days apart. 2-part shrink discs (displacement-controlled) have a defined Aufschubweg, as a result, the installation can be done without a torque wrench. The span of the 2-part shrink disc screws (displacement-controlled) have to be tightened evenly so around the table until the end of the sleeve is flush to the front side of the pressure ring. In the catalog specified torques can be transferred as soon as this Monday state is reached.

2-panel shrink discs (displacement-controlled) is available in 3 different versions. For the smallest torque and small spaces, the series TAS 3173 offers. At high, to very high transmissible torques, can be between the TAS 3381 and the TAS 3393 chosen. Depending on the space that is available, and the required torque, we will find together the right solution for you. Also, for a special anti-corrosion protection, or low-temperature environments, appropriate solutions can be offered.

2-part shrink discs (displacement-controlled) can transfer 20% -30% higher torques. In connection with the simplified handling, have proven to be the 2-part shrink discs (displacement-controlled), especially in the field of mining and conveyor technology in practice. By default, this shrink discs, but in the whole area of frictional shaft-hub-Connections, e.g., the drive technology, Oil and gas industry, wood industry or hollow shaft transmissions.

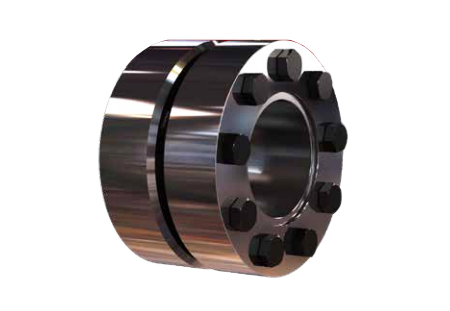

FLANGE SHRINK DISCS COUPLINGS :

• High transmissible torques with short installation length

• Transmission of dynamic loads

• Transmittable torque of 830Nm to 2.742.000 Nm

• Nominal diameter of 38mm up to 500mm

• Individual special solutions possible

• Special anti-corrosion protection possible

The flange couplings of the series "FK" use Shrink Discs for the connection of two shafts. It is a strong Rigid solution!! This can be used as a whole flange coupling consisting of 2 Flanges and 2 shrink discs or, alternatively, as half-flange coupling, consisting of a Flange and a shrink disc to be. The main function of a rigid flange coupling is secure and free of Play, connect two shafts by means of frictional contact. These Shrink Disc Coupling simplify the installation on the respective shaft ends. The Flange-mounted shrink discs to create a backlash free connection by pressing the flange hubs on the shaft. Flange Shrink Disc couplings are in the first line of these torques are designed to transferbending moments and axial forces.

The flange shrink disc coupling are mounted, provide the required forces and transferred even halves of no force or torque between Shafts Couplings and Flange Couplings. It is assembled easily by the Sliding of each of the Flange on the shaft ends with Shrink Discs. In the last step, each of the flange to be connected halves by means of a screw.

TAS flange Shrink Disc coupling of the series "FK" find their application in the marine technology, wind power technology, conveyor technology, mixing and process engineering, hydropower engineering, as well as in crushing plants and elevators.

DAMPING TECHNOLOGY :

• High spring work with low weight and volume

• In Block overload-proof

• High Attenuation

• Maintenance-free

• Force-displacement diagram is independent of the load speed

Friction springs and "RF" are vital safety components must be included in all the technical areas in which sudden forces and kinetic energy, or springs with high force in a relatively small dimensions are required. Friction springs and "RF" are used where large amounts of kinetic energy and steamed absorbed, or a relatively small spring size is required, to high forces to withstand. The areas of application of the friction springs and "RF" are very diverse. Here, overload protection, glass path and energy absorption are mainly offered in three performance aspects, which can also be combined with each other.

Friction springs and "RF" consist of Outer and inner rings, the touch of your cone surfaces with the use of a special lubricant. An axial load on the spring column, the effect of the conical surfaces slides against each other, and each Ring is elastically deformed. This means that the outer ring is stretched and the inner ring is compressed. The resulting spring deviation is calculated from the change in Diameter of the elastic deformation of the ring and the cone angle.

Compared to other types of Spring, the Circumferential stress is distributed nearly uniformly over the cross section of the loaded spring element, so that each component is evenly utilized. This is a lighter friction spring "RF in comparison to other similar types of springs". The special characteristics of the friction spring, the strong friction damping of about two-thirds of the introduced energy is The strength of TAS Schäfer GmbH is the flexibility of its own production. With a highly competent design Department, we are able to produce special solutions for our customers. We will be happy to work together with you to find a solution to your requirements and needs. In our own raw material warehouse at the location of the weather, we can also realize in the case of special solutions with short delivery times and our customers as a reliable Partner in the short-term support.

On request, TAS Schäfer products can be also delivered with the acceptance of a classification society or comprehensive documentation by measuring the center.

About Power Ace India :

Power Ace India is one of the leading gear manufacturers in India providing power transmission solutions. We also specialize in shrink disc couplings and torque limiter coupling. Power ace India offers a wide range of locking assembiles that cater to multiple industrial applications. Our products, including 90 degree gearbox provide secure and reliable shaft-hub connections. As one of the reliable gear manufacturers in India, power Ace India continues to be a number one choice for industries seeking for durable and efficient power transmission solutions.

Products