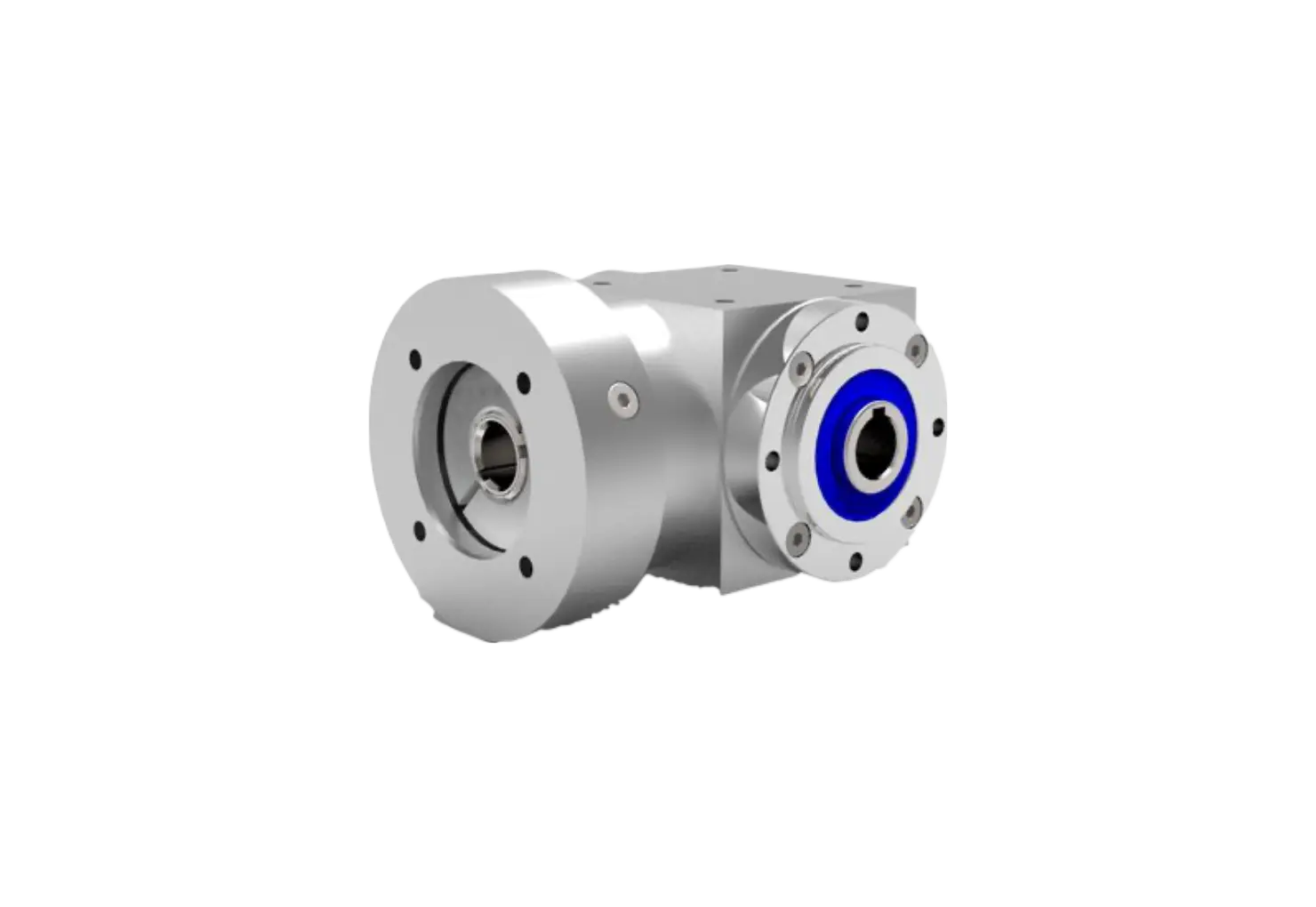

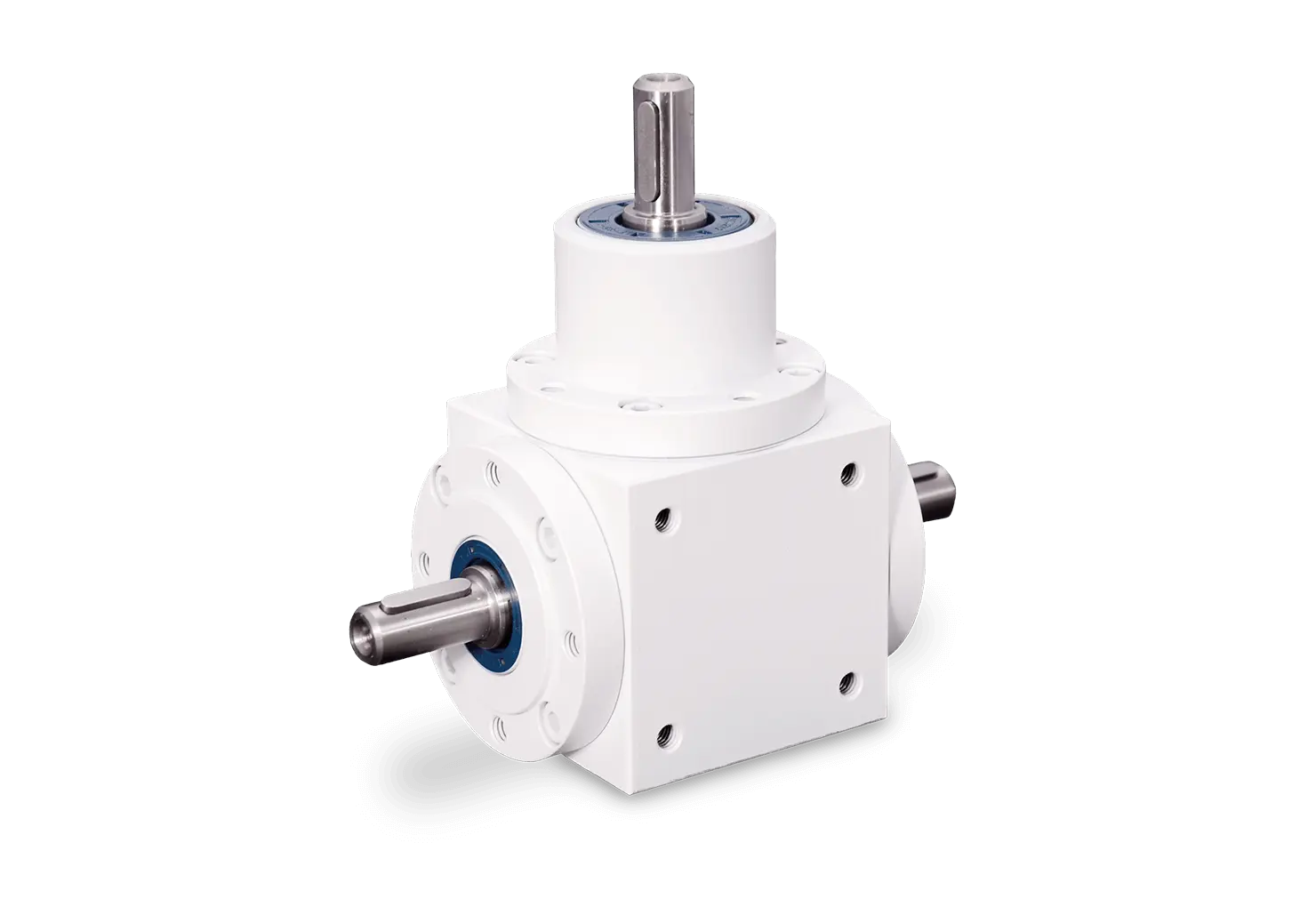

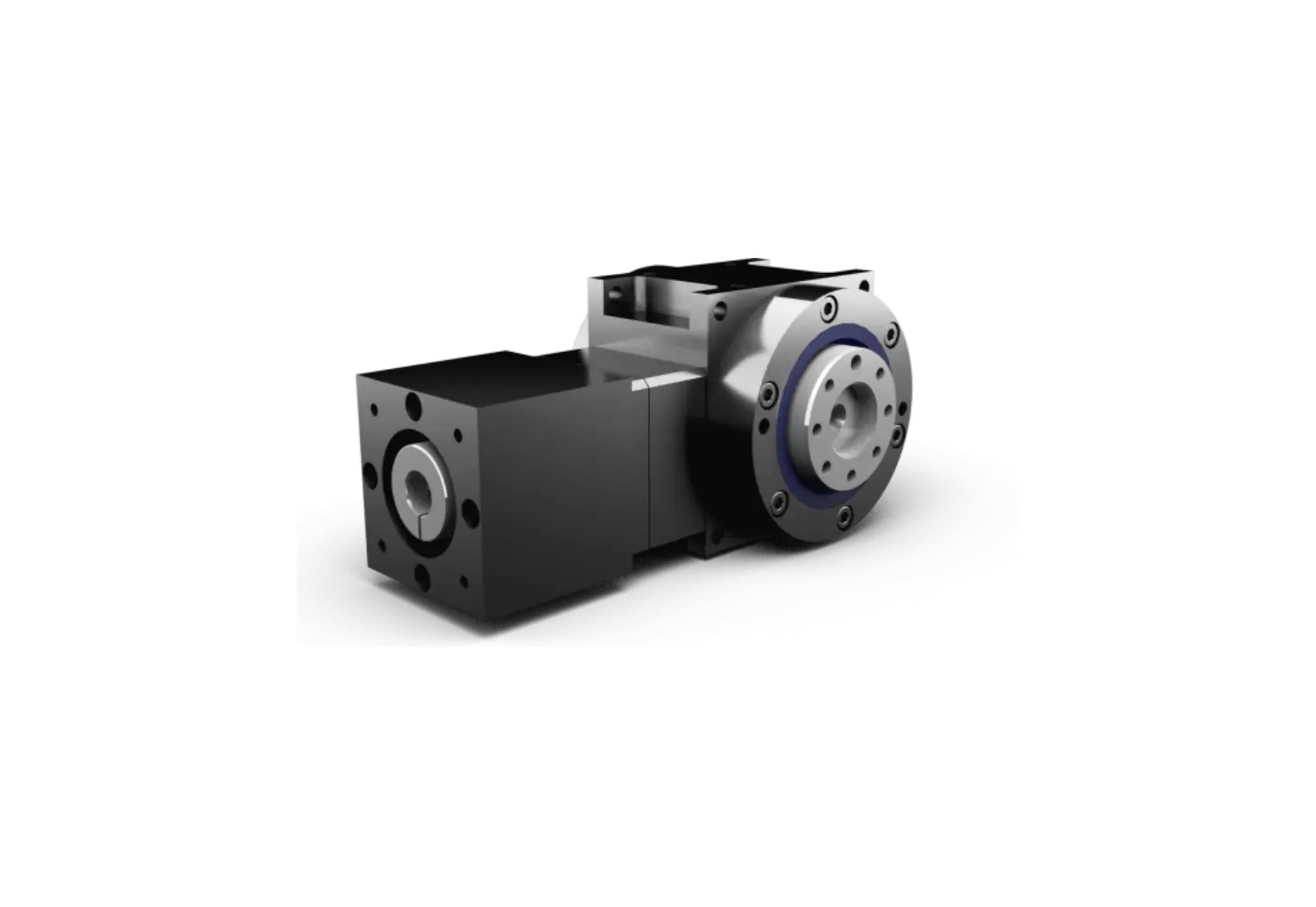

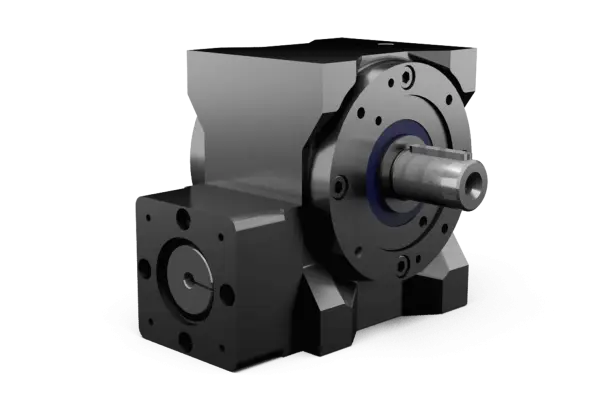

Right Angle, 90 Degree and Precision Gearboxes Precision Right Angle Gearbox

Get Ready to Work With the Most Professional Right Angled Gearbox Manufacturers

When the driveshaft and the output shaft are arranged at a right angle, it can be characterised by a Right Angle Gearbox. The axis can intersect in a plane or cross on 2 parallel lines depending on the gearbox type and can result in an axis offset.

The 90 degree gearbox is realised with a combination of different types of gears or various types of gearing teeth. The most widely used single-stage gearbox types are bevel and worm.

The worm gearbox can achieve a self-locking effect because of the high single-stage ratios and low efficiency levels. They make it possible to have a hollow shaft as the driveshaft. The bevel gearbox comes with different types of gearing. The bevel gearboxes with intersecting axes can be realised using bevel gearing with straight, spiral and helical teeth. A bevel gear stage can be realised with a bigger bandwidth of technically sensible ratios with hypoid gearboxes as compared to classical bevel gear teeth. Different gearbox types can be combined with bevel gearboxes and used in applications like the combination with a planetary gearbox, whereby the planetary gearbox can be connected upstream or downstream. This leads to a wide range of overall multiplication factors and makes them fit for use in many industrial applications.

The running noise and the transmittable torques of bevel gearboxes by Power Ace are lower as compared to single spur gear teeth and offers torque limiter coupling which helps to prevent any severe damage to our gearboxes. Our right-angled gearbox is majorly used when the amount of installation space in the application is limited or an angular arrangement between the drive and the output is needed by the application. They are also utilized in places where the input shaft needs to be hollow in order to lead through lines or use clamping sets.

Why Choose Power Ace?

Power Ace is one of the leading distributors of precision gearbox. Based on years of experience and the highest level of technical production capabilities, Power Ace is fully equipped to design and build a technically advanced, high-speed, with shrink disc, and low backlash diverse application planetary gearbox. The team of experts at Power Ace delivers nothing less than low-profile planetary gearing and precision ground spiral bevel right angle gears that provide smooth, quiet operation and reliable accuracy making them one of the leading gear manufacturers in India.

With various types of right angle gearbox including miniature spiral, worm, spiral bevel, hygiene design, spiral hypoid, and right angle planetary gearbox, we provide everything under one roof. We strive to constantly improve our processes, find proper and effective methods and provide customers with new solutions for difficult applications and giving rise to new products.

Products